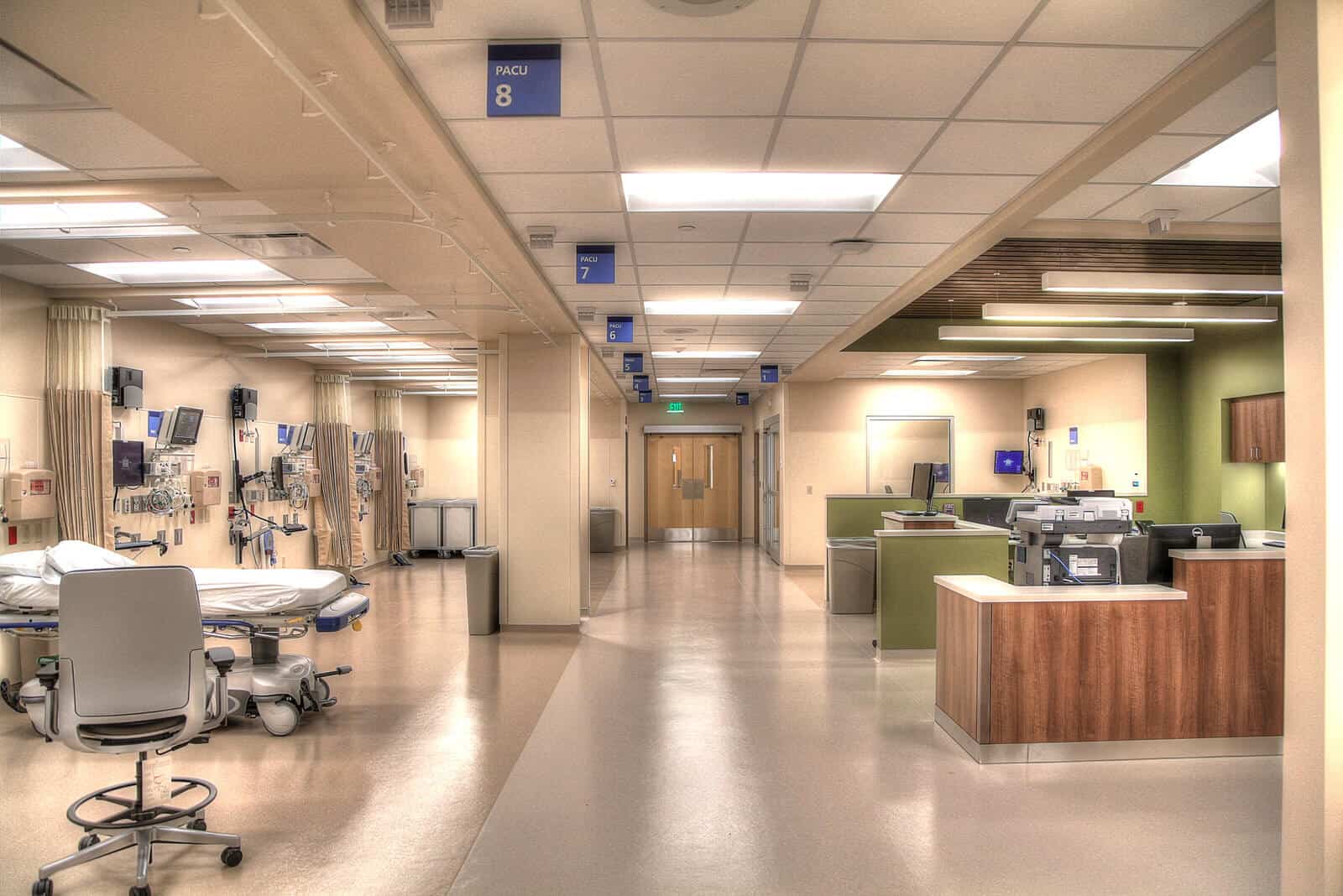

American Fork Hospital: Surgical and Emergency Addition

This was an 84,000 square foot addition to the existing hospital campus. It provides a new home for the hospital Surgical Services and Emergency departments. Ten new 550 square foot operating rooms were constructed and eight are operational today. Along with the OR’s, new pre-op, post-op and PACU patient rooms were provided. The OR’s include cutting-edge technology including integrated video monitoring and mobile imaging. Two of the OR’s are orthopedic suites with a third being equipped as a urology suite. The Emergency Department provides 21 individual private rooms, an emergency dental room, a psych room as well as two state-of-the-art trauma rooms. The design was optimized for patient safety and comfort.

Adjacent to the ER, a new Decontamination and Sterilization Central Processing area was installed. The facility cleans and preps all the tools needed to provide for functioning of the hospital. The 24,000 square foot area included parts washers, cart washers as well large autoclaves. It is large enough to provide for the future needs of the hospital as it grows.

The addition has a new 2,000A 480V normal power service fed from Rocky Mountain Power. Normal, emergency and critical power was distributed throughout the project. A major component of the project was the relocation of both of the existing emergency diesel generators serving the hospital. This had to be completed while the hospital remained 100% operational. The larger of the two generators was located in the basement of the north tower. The emergency power had to be brought 1,200 feet from the new location back to refeed the existing hospital and services. This was accomplished by installing a step-up medium voltage transformer to change power 4,160V in order to reduce the voltage drop over the distance. At the original location of the generator, another medium voltage transformer was installed to reduce the voltage back to 480V. Furthermore, a control system had to be installed to monitor and control the two generators so they functioned in unison further complicating the installation. Additions were made to the Central Utility Plant (CUP) including new chillers and cooling tower to support the new space.